Tag: kitchen ventilation

-

A Primer on Maintaining Your Commercial Kitchen Ventilation System

Proper maintenance of your kitchen ventilation system can sometimes be overlooked. Some requirements, such as duct cleaning, are code mandated, while others are discretionary. It is safe to say that maintenance is often viewed as an expense (from an accounting perspective, it is) but should be viewed as an investment in trouble-free operation. A commercial…

-

The Radiant Chef

How does radiant heat affect your chef’s and kitchen staff comfort? Typically, if you tell someone they look “radiant,” you would be complimenting their glowing appearance. If you tell a chef that they look radiant, it probably means they look hot and uncomfortable. Let’s explain how radiant heat affects the comfort of not only your…

-

Ghost Kitchen Exhaust Success Routine

The commercial kitchen ventilation (CKV) industry has done a great job of defining the step by step approach for optimizing CKV design by focusing on the four key areas of: exhaust hood, exhaust fan, replacement air and controls. The goal of course is to develop a design that effectively captures, contains and exhausts the heat…

-

What You Get for Free When Specifying Short-Circuit Exhaust Hoods

KitchenVentilation.com is pleased to have guest Blogger, Steve Brown, Member of ASHRAE provide his take on the origins of short-circuit exhaust hoods. The history of short-circuit exhaust hoods. The price controls and energy shortages of the 1970’S “Dark Decade for Energy” began in 1954 with the United States Supreme Court’s decision in “Phillips Petroleum Co.…

-

Taking a Deeper Dive, Cooking Odors, and Why Are They Such A Challenge to Mitigate?

It suffices to say most cooking odors are pleasant when in small doses. Where issues arise is when you have very active foodservice operations that are adjacent or part of residential dwellings. It is in these situations or when mandated by a landlord or code that minimizing the impact of nuisance cooking odors takes on…

-

What are UltraViolet lights in kitchen hoods used for and what outcome can I expect when using them?

Ultraviolet Lights or UV-C lights are a type of bulb that has a very high intensity that allows it to break down organic compounds. UV has been applied in a variety of sterilization and water treatment applications for decades. The wavelength varies by application. In the case kitchen exhaust systems, UV-C light is used to…

-

I’ve Seen Ventilated Ceilings for Kitchens in Europe. Can they be used in North America?

In a word yes, Ventilated Ceilings can be installed in North America, assuming it is listed for that purpose. Let’s talk about what a Ventilated Ceiling is. It is an alternative to the traditional canopy and island hoods seen in most installations in North America. Effectively, the Ventilated Ceiling System is the exhaust and supply…

-

How can you have balancing dampers in a grease duct? I thought they were not allowed?

Here’s what NFPA 96 has to say about balancing dampers in commercial kitchen exhaust ducts. Chapter 9 Auxiliary Equipment 9.1 Dampers. 9.1.1 Dampers shall not be installed in exhaust ducts or exhaust duct systems. 9.1.2 Where specifically listed for such use or where required as part of a listed device or system, dampers in exhaust…

-

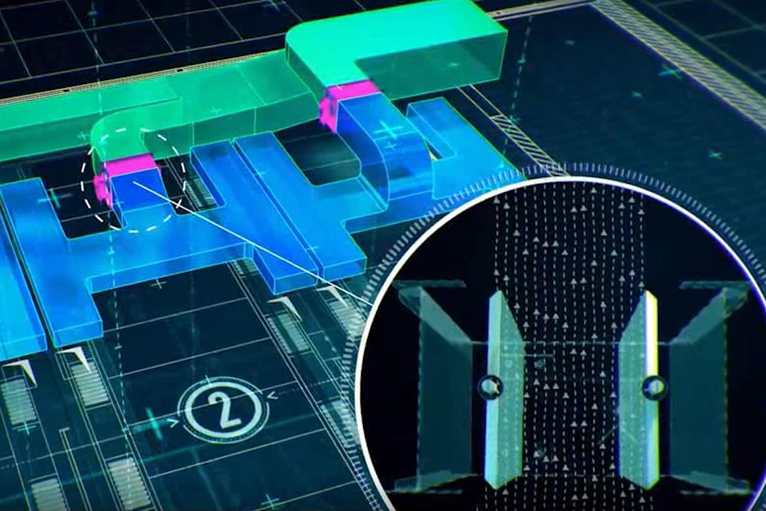

Demand Control Ventilation Systems for Commercial Kitchens, how do they differ, how are they the same?

The number and type of Demand Control Kitchen Ventilation (DCKV) systems for commercial kitchens have grown significantly in recent years. This can be attributed to several factors, principally the adherence to ASHRAE 90.1 ventilation standard. This is the standard that affects design for commercial kitchens, and it states that on exhaust systems greater than 5000…

-

How not to ruin a good thing, Make-up Air 101

Hey, it’s your birthday! Go ahead and inhale those candles out! What? You don’t suck the flame off the candle? Have you ever tried? Yes, it’s a silly anecdote and a very effective one (thanks, Dr. Livchak!). As most of us know, we blow out our candles. The physics works well and accomplishes the job…